|

1. Method applied for measuring the properties of the sample oils The following methods were applied to measure the properties of the sample oils. Emulsified sample oil ("mouse" formed) was measured after placing it on filter paper and removing the free water. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| @ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

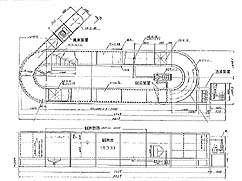

2. Conditions of the circulating water channel experiments. 2 types of waves were used for this experiment: corresponding

to wave ranks, "1" (referred to as "weak waves" throughout the rest

of this paper) and "2" (referred to as "strong waves" throughout

the rest of this paper), authorized by the Japan Meteorological

Agency. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| @ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3. Testing method @The various apparatuses of the circulating water channel

were set according to the conditions shown in Table 2 for each case

in this test. In a waves stable state, the test oil of predetermined

amount was poured calmly on surface of the circulating sea water.

First day, the samples of test oil were taken after 0.5, 1, 2, 4,

6, 8 hour from the surface of sea water. After that the samples

were taken at 24 hour intervals over a period of 4 days from the

surface of sea water. And the properties of sample measured viscosity,

water content, density and evaporation rate. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

HOME PAGE : http://www.pcs.gr.jp@E-mail : mail@pcs.gr.jp |

|

Copyright, 2000 PAJ All rights reserved |